Medium-pressure UVA curing lamps (also known as MPUV or MPHO lamps) are mercury-vapor UV lamps that strike a balance between the low-pressure and high-pressure extremes. Operating at typically 1 atmosphere of internal pressure, these lamps produce a broad spectrum

of UV radiation rather than the single line of a low-pressure lamp. In fact, a medium-pressure UV lamp emits a continuum of UV wavelengths spanning UVC (≈200–280 nm), UVB (280–315 nm), and UVA (315–400 nm), as well as some visible and infrared light. This polychromatic UV output is one of the defining characteristics of medium-pressure lamps and is crucial for specific processes.

For UV curing applications, the UVA portion (around 365 nm and above) is especially effective at initiating free-radical photopolymerization in inks, coatings, and adhesives. At the same time, medium-pressure lamps’ emission of germicidal UVC wavelengths allows them to serve dual purposes in some systems (for example, curing a coating while also disinfecting a surface).

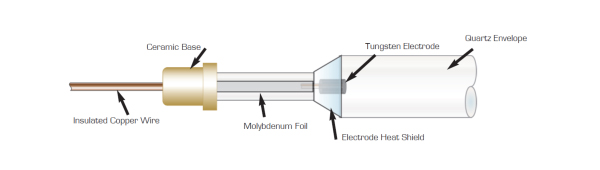

These lamps are typically “arc lamps” with tungsten electrodes sealed at each end of a quartz tube filled with a small amount of mercury and an inert gas. Once ignited, the mercury plasma reaches temperatures of 600–900 °C, and the lamp can operate at power levels from a few kilowatts up to tens of kW for the largest lamps.

Medium Pressure UVA Curing Lamps Performance and Advantages

Compared to low-pressure UV lamps, medium-pressure UVA lamps deliver UV intensity orders of magnitude higher. They can be run at power densities ranging from roughly 100 W/inch to 700+ W/inch, resulting in extremely high irradiance on the target. This high intensity means shorter exposure times are needed to achieve complete curing – an essential advantage for high-speed manufacturing. Indeed, MPUV lamps are often the best choice when a process has limited UV exposure (e.g., a fast-moving conveyor) or when UV must penetrate pigments or thick films (the broad spectrum increases the likelihood of reaching photoinitiators at various depths).

Medium-pressure UV systems can dramatically improve production throughput; a part coated with UV varnish can be cured in seconds as it passes under MPUV lamps, whereas traditional thermal curing might take minutes or more. Additionally, because of their broad spectral output, medium-pressure lamps can simultaneously activate photoinitiators with different absorption peaks, potentially curing multi-component formulations more uniformly.

Another advantage is the compact size relative to output. An MPUV lamp assembly can be much smaller than an array of low-pressure lamps needed to deliver equivalent UV energy. This compact footprint is beneficial for retrofitting UV curing into existing production lines with limited space. For instance, medium-pressure lamps are used in marine ballast water treatment because a single MPUV lamp can disinfect water at flow rates that would otherwise require dozens of low-pressure lamps, saving space in the tight confines of a ship. The same principle applies in curing units – a few medium-pressure lamps can cover a wide curing area or achieve a high line speed, simplifying system design.

LightSources Quality MPUV Curing Lamp Construction

To reliably generate such high UV outputs, medium-pressure lamps must be built to exacting standards. LightSources constructs all MPUV lamps using premium fused quartz tubing that has extremely low impurities and water content. This ensures the quartz can withstand high temperatures and transmits UV effectively (ordinary glass would block UVC and degrade under the intense heat). The electrode design is another critical factor: we use pure tungsten pin electrodes because tungsten has a very high melting point and can endure the thermal stress. Each electrode is wrapped with a coil of thoriated tungsten (a tungsten alloy with a trace of thorium oxide). This

over-wind

enhances the electrode’s electron emission and prolongs lamp life by reducing sputtering. The ends of the lamp are sealed using molybdenum foil encased in a quartz press (sometimes called a hermetic “Danner” seal). The molybdenum foil serves as a reliable electrical feed-through and maintains a vacuum-tight seal even as the lamp cycles through high temperatures.

These construction features collectively yield a lamp of exceptional durability and stability: our medium-pressure lamps can often run for 1,000–5,000 hours (depending on power level) with minimal degradation in UV output. This longevity and output stability (usually ~80–90% of initial output even near the end of life) mean fewer lamp replacements and consistent curing quality over time.

For added versatility, LightSources can fabricate medium-pressure UV lamps in various forms. While the most common shape is a straight (linear) tube, we also offer “U-shaped” or circular medium-pressure lamps and even helical (coiled) designs for compact systems. Arc lengths range from just 1–2 inches to ~90 inches (2.5 cm to 2.3 m) to suit everything from small lab curing boxes to large industrial applications. We can equip the lamps with either ceramic or metal end bases of virtually any style – our subsidiary Cerlux provides custom ceramic bases in any requested color and configuration. This means integration into your equipment is seamless, whether you need a specific pin configuration or a unique mounting flange.

Medium-Pressure UVA Curing Lamp Applications and Industries

Medium-pressure UVA lamps are used broadly across industries. Some notable application areas include:

- Printing and Coatings: UV curing of inks (e.g., on high-speed printing presses for magazines, labels, packaging), varnishes, and lacquers. Medium-pressure lamps are standard in many graphic arts curing systems because they cure ink on paper or plastic in milliseconds, preventing smudging and allowing immediate post-print handling. They’re also used for curing protective clearcoats on wood flooring, furniture, and automotive components.

- Adhesives and Electronics: Curing of UV-reactive adhesives in assembly lines (e.g., bonding electronics, medical device assembly). Medium-pressure lamps can quickly cure adhesives in joints or coatings on PCBs, often in automated production, without slowing the line.

- Industrial and Automotive:Automotive manufacturers use medium-pressure UV lamps to cure paints, sealants, and specialty polymer coatings on parts such as headlights and interior trim, as well as for minor scratch repair. The lamps’ high intensity allows curing on moving assembly lines, increasing throughput. Similarly, in fiber optics production, MPUV lamps cure the polymer coating on fibers almost instantaneously as the fiber is drawn.

- Air and Water Treatment (Dual-use): Some systems leverage the broad output of medium-pressure lamps to perform

advanced oxidation processes

(AOPs

)

for pollution control. For example, a medium-pressure lamp in water emits both UVC (for direct disinfection) and UV-V (near-visible) radiation, which, in the presence of catalysts, generate radicals that break down contaminants. These lamps are used in wastewater plants for both disinfection and the degradation of organic pollutants in a single unit. While this is more of a disinfection application, it underscores the power and versatility of medium-pressure UV sources.

Overall, medium-pressure UVA curing lamps are often the workhorse of UV curing – delivering a potent, broad-spectrum UV dose that can handle diverse materials and fast processes. They strike an excellent balance for many applications, providing much higher intensity than low-pressure lamps but without the need for the very specialized doping of high-pressure metal halide lamps (though, as mentioned, medium-pressure lamps can be doped when needed). LightSources continues to innovate in this category, offering state-of-the-art medium-pressure lamps

that incorporate the latest materials and electrode designs for even greater efficiency and longevity.

UV Curing Lamp Customization and Support

When selecting a medium-pressure UV lamp, matching the lamp’s characteristics to the application is key. LightSources provides technical support to determine the optimal wavelength and power level for your curing process. If your process involves a unique polymer that responds to a specific UV band, we can adjust the lamp design or recommend an additive. Our engineers can also assist with power supply selection, cooling requirements (medium-pressure lamps often require forced-air or water cooling in the lamp housing), and control systems (e.g., shutter mechanisms or dimming controls for the lamps). Many of our medium-pressure lamps can be run at variable power – for example, you can have a lamp operate at 50% power during idle times and ramp to 100% when product is present, extending lamp life and saving energy. We ensure that our custom lamps integrate reliably into such systems.

Furthermore, we understand that OEMs may need private-label solutions – we can brand the lamps with your part numbers or labels, and package them for direct inclusion in your kits or machines. Quality is assured through our ISO 9001:2015 certified manufacturing and rigorous testing of every lamp’s electrical and UV output parameters.

LightSources offers MPUV curing lamps,

High-Pressure Curing Lamps

, and

Low-Pressure UVC Amalgam Curing

lamps with custom design and engineering to meet your specific requirements.

Learn more about

UV Curing

,

UV Curing Applications

, and explore our

Educational Resources

on UV Curing, including FAQs, Downloadables, and a UV Curing glossary.

Each lamp is pumped and filled with inert Argon gas in an exacting process that ensures total accuracy of fill pressure and mercury content. The lamp is then completed with a metal or ceramic base and a suitable electrical termination. Each lamp has a serial number enabling complete traceability from start to finish in the production and measurement process.

Interested in learning more about MPUV lamps and UV curing applications? Go ahead and browse through our large MPUV education and FAQs section

.

By choosing LightSources for medium-pressure UV lamps, customers gain a trusted partner with decades of experience in UV technology, ensuring the lamps not only meet specifications on paper but also excel in real-world operation with maximum uptime and performance. Contact us to speak with an engineer about your UV curing application and how to select the best medium-pressure UVA curing lamp.

Medium Pressure UVA Curing

Table of Contents

For UV curing applications, the UVA portion (around 365 nm and above) is especially effective at initiating free-radical photopolymerization in inks, coatings, and adhesives. At the same time, medium-pressure lamps’ emission of germicidal UVC wavelengths allows them to serve dual purposes in some systems (for example, curing a coating while also disinfecting a surface).

These lamps are typically “arc lamps” with tungsten electrodes sealed at each end of a quartz tube filled with a small amount of mercury and an inert gas. Once ignited, the mercury plasma reaches temperatures of 600–900 °C, and the lamp can operate at power levels from a few kilowatts up to tens of kW for the largest lamps.

Medium Pressure UVA Curing Lamps Performance and Advantages

Compared to low-pressure UV lamps, medium-pressure UVA lamps deliver UV intensity orders of magnitude higher. They can be run at power densities ranging from roughly 100 W/inch to 700+ W/inch, resulting in extremely high irradiance on the target. This high intensity means shorter exposure times are needed to achieve complete curing – an essential advantage for high-speed manufacturing. Indeed, MPUV lamps are often the best choice when a process has limited UV exposure (e.g., a fast-moving conveyor) or when UV must penetrate pigments or thick films (the broad spectrum increases the likelihood of reaching photoinitiators at various depths).

Medium-pressure UV systems can dramatically improve production throughput; a part coated with UV varnish can be cured in seconds as it passes under MPUV lamps, whereas traditional thermal curing might take minutes or more. Additionally, because of their broad spectral output, medium-pressure lamps can simultaneously activate photoinitiators with different absorption peaks, potentially curing multi-component formulations more uniformly.

Another advantage is the compact size relative to output. An MPUV lamp assembly can be much smaller than an array of low-pressure lamps needed to deliver equivalent UV energy. This compact footprint is beneficial for retrofitting UV curing into existing production lines with limited space. For instance, medium-pressure lamps are used in marine ballast water treatment because a single MPUV lamp can disinfect water at flow rates that would otherwise require dozens of low-pressure lamps, saving space in the tight confines of a ship. The same principle applies in curing units – a few medium-pressure lamps can cover a wide curing area or achieve a high line speed, simplifying system design.

LightSources Quality MPUV Curing Lamp Construction

To reliably generate such high UV outputs, medium-pressure lamps must be built to exacting standards. LightSources constructs all MPUV lamps using premium fused quartz tubing that has extremely low impurities and water content. This ensures the quartz can withstand high temperatures and transmits UV effectively (ordinary glass would block UVC and degrade under the intense heat). The electrode design is another critical factor: we use pure tungsten pin electrodes because tungsten has a very high melting point and can endure the thermal stress. Each electrode is wrapped with a coil of thoriated tungsten (a tungsten alloy with a trace of thorium oxide). This over-wind enhances the electrode’s electron emission and prolongs lamp life by reducing sputtering. The ends of the lamp are sealed using molybdenum foil encased in a quartz press (sometimes called a hermetic “Danner” seal). The molybdenum foil serves as a reliable electrical feed-through and maintains a vacuum-tight seal even as the lamp cycles through high temperatures.

These construction features collectively yield a lamp of exceptional durability and stability: our medium-pressure lamps can often run for 1,000–5,000 hours (depending on power level) with minimal degradation in UV output. This longevity and output stability (usually ~80–90% of initial output even near the end of life) mean fewer lamp replacements and consistent curing quality over time.

For added versatility, LightSources can fabricate medium-pressure UV lamps in various forms. While the most common shape is a straight (linear) tube, we also offer “U-shaped” or circular medium-pressure lamps and even helical (coiled) designs for compact systems. Arc lengths range from just 1–2 inches to ~90 inches (2.5 cm to 2.3 m) to suit everything from small lab curing boxes to large industrial applications. We can equip the lamps with either ceramic or metal end bases of virtually any style – our subsidiary Cerlux provides custom ceramic bases in any requested color and configuration. This means integration into your equipment is seamless, whether you need a specific pin configuration or a unique mounting flange.

Medium-Pressure UVA Curing Lamp Applications and Industries

Medium-pressure UVA lamps are used broadly across industries. Some notable application areas include:

Overall, medium-pressure UVA curing lamps are often the workhorse of UV curing – delivering a potent, broad-spectrum UV dose that can handle diverse materials and fast processes. They strike an excellent balance for many applications, providing much higher intensity than low-pressure lamps but without the need for the very specialized doping of high-pressure metal halide lamps (though, as mentioned, medium-pressure lamps can be doped when needed). LightSources continues to innovate in this category, offering state-of-the-art medium-pressure lamps that incorporate the latest materials and electrode designs for even greater efficiency and longevity.

UV Curing Lamp Customization and Support

When selecting a medium-pressure UV lamp, matching the lamp’s characteristics to the application is key. LightSources provides technical support to determine the optimal wavelength and power level for your curing process. If your process involves a unique polymer that responds to a specific UV band, we can adjust the lamp design or recommend an additive. Our engineers can also assist with power supply selection, cooling requirements (medium-pressure lamps often require forced-air or water cooling in the lamp housing), and control systems (e.g., shutter mechanisms or dimming controls for the lamps). Many of our medium-pressure lamps can be run at variable power – for example, you can have a lamp operate at 50% power during idle times and ramp to 100% when product is present, extending lamp life and saving energy. We ensure that our custom lamps integrate reliably into such systems.

Furthermore, we understand that OEMs may need private-label solutions – we can brand the lamps with your part numbers or labels, and package them for direct inclusion in your kits or machines. Quality is assured through our ISO 9001:2015 certified manufacturing and rigorous testing of every lamp’s electrical and UV output parameters.

LightSources offers MPUV curing lamps, High-Pressure Curing Lamps , and Low-Pressure UVC Amalgam Curing lamps with custom design and engineering to meet your specific requirements.

Learn more about UV Curing , UV Curing Applications , and explore our Educational Resources on UV Curing, including FAQs, Downloadables, and a UV Curing glossary.

Each lamp is pumped and filled with inert Argon gas in an exacting process that ensures total accuracy of fill pressure and mercury content. The lamp is then completed with a metal or ceramic base and a suitable electrical termination. Each lamp has a serial number enabling complete traceability from start to finish in the production and measurement process.

Interested in learning more about MPUV lamps and UV curing applications? Go ahead and browse through our large MPUV education and FAQs section .

Click here for more information on the types of cookies we use and how to change your cookie settings. Accept

Privacy Overview

1-800-826-9465 (North America)

+44 1576 220246 (Europe Germicidal)

+36 2754 1800 (Europe Other)

+86 21 52662921 (China)